Troyer's Rope Company

The Troyer Rope Company’s origin started back in 1965 when Andrew Troyer (Andy) and his dad went to a local auction to bid on a rope-twisting machine. While his dad made a bid for the machine, they were unable to get the highest bid and it was sold to another family for $8.00. Even at this young age, the way the rope is made was still continuing to dwell in his mind. How can rope be made in a series of three different processes of twisting the yarn but does not pull apart and unravel? Since the Troyer's did not purchase the rope machine, they decided to build their own machine and tinker around with it. This enabled Andy to hone his rope-making skills.

As Andy grew into a young adult, he entered the teaching profession in 1977 and married in 1978. While teaching school in Ohio, he decided that he wanted the student to get some practical experience and brought in his rope machine. Shortly after that lesson, he received an order from one of the student's dads to make 6 lead ropes. Then another order came in for 6 more and then after that 12 more. This was the start of the Troyer's Rope Company.

After teaching and making rope part-time, he decided that he couldn’t devote the time he needed to teach his students, so he moved full-time to his rope company in 1986. After working at the business for several years realized he needed more room to grow the business. In 1990 he left Ohio and moved to the small Amish community just outside of Conneautville. Pennsylvania. He set up shop in a small barn and began twisting rope. Because of the demand to make a 600-foot spool of rope, he employed family members and set up the rope walk. A ropewalk is a long straight narrow lane, or a covered pathway, where long strands of material are laid before being twisted into rope. Three people could make 6,000 feet of rope in 3 hours. This was the equivalent of walking 9 miles. The rope was used for many years before braided rope took over the demand for the twisted. Over the years Troyer Rope continued to grow as they moved into a larger facility in 2005 and in 2021 they moved into their current facility which is over twice the square feet where they are the largest Amish employer in the area.

They are continuing to grow the business and have become one of the largest manufacturing and distribution centers for the agricultural industries. They are supplying the country with halters for the fair and 4-H clubs.

Over the years Andy’s oldest son Adam was working in the business and when he was only 16 was talking to customers and making yarn purchases. Many of these customers and vendors thought that Adam was much older than he was. Faith and Family are the keys to Andy’s life and in 2012 he was able to bring Adam into the business as a partner and currently Adam is in charge of the daily operations and is taking the company into more directions and industries. Andy has stepped back from the business to do more consulting and now is focusing his life on writing and spending more time with his wife and youngest son.

Family is everything.

Andy has been blessed with working with his family throughout his career. Per Andy, "that is the icing on the cake." His three sisters spent their entire life working for Andy in the rope business and have recently retired from the business. To this day, Andy is making sure that his sisters are provided for. Two of Andy’s sons-in-law are also actively working in the business. Family working together is such a great opportunity.

As we look back on the history of Troyer Rope, Andy has seen many changes in the industry.

- Many rope companies are now focusing on just making mass quantities of rope and not quality anymore. Troyer Rope has stayed with providing quality rope and stayed simple enough to slowly grow the business to where they are today. While Troyer Rope has been keeping up with the technology of braiding machines, they are not all about just making rope. They must produce a quality rope that customers will return to each year.

- Switching from a twisted rope to a solid braided rope. These are softer, smoother, and more colorful than twisted. In the Amish horse industries, they serve over 2800 corporate clients who know that it is so much nicer to tie a horse with a softer rope. Machine made braided rope is now the norm as that is what the customer wants.

- The color choices. When Troyer Rope started they started only with blue, then green, and then eventually up to 10 basic color choices. However, as the customer's taste changed and wanted more, Troyer Rope evolved with that. They currently have 21 different colors that make 105 different braided combinations in 6 different sizes. However, that still isn’t enough. Through research and customer requests, they look to continue offering more color choices in the future.

- The work ethic is changing in America and in many parts is declining. Many companies, have a hard time finding employees and have had to outsource many manufacturing positions. Troyer Rope has a great workforce and is manufacturing in several locations throughout Pennsylvania and Ohio and all of their labor is here in the USA.

As we stated earlier Faith and Family are the ideals that are firmly in place in Andy’s heart.

* “Blessings to your family, customers, nation, and community”

* “God blesses his people and passes on His blessings to others”

*“Serve the Lord and the Public”

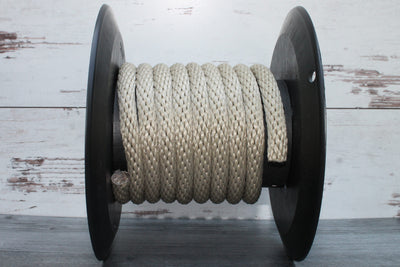

Troyer's Solid Braided Multifilament Polypropylene Rope

Solid Braided Multifilament Polypropylene Rope is known as “An All-Purpose, Utility Rope.” It is a blend of nylon and polypropylene. Polypropylene is a hardy synthetic fiber resistant to many types of solvents and glues. The rope is woven from three-strand yarn making it extremely durable and strong. Polypropylene also has a higher melting point than most common polymers, making it resistant to heat and friction. We offer Solid Braided Multifilament Polypropylene Rope in many sizes and colors for any project you need. It ties nicely, is washable, user-friendly, super soft, and colorful.

Features of Solid Braided Multifilament Polypropylene Rope that make it so useful

- Resists mildew, rot, and UV rays

- Floats in water

- Moderate strength. Similar in strength to polyester

- Low stretch

- Machine washable and quick to dry

- Holds up well in severe weather

- Easy to practice making knots with

- Abrasion resistant

- 105 colors and color combinations available

- Inexpensive compared to other synthetic rope material

What is Solid Braided Multifilament Polypropylene Rope used for

- Since this rope floats on water, it is used in swimming pools to rope off lanes and designate the shallow end from the deep end. It is also used for other water sport applications.

- The low stretch feature makes this rope perfect for travel to tie down coolers and roof racks. Keep this rope handy when moving to tie moving blankets to furniture and other things that you want to keep from sliding about the truck.

- “This is the rope that derby people love!” Tie your prize horse to a hitch with ease using this Polypropylene rope. It also makes beautiful halters with many, many colors to choose from.

- There are countless uses for this rope when going on outdoor adventures.

- Camping tent line

- Kayaking and boating – tie up the vessel to its moorings so it does not drift out to sea and other practical maritime applications.

- Makes a sturdy hammock

- It is the best rope for making a swing

- Make a rope bridge or ladder for a treehouse.

- Ropes courses

- Solid Braided Multifilament Polypropylene Rope has many uses on farms and ranches

- Perfect for lassos

- Barn and stable rope

- Tie bales of hay down when transporting for sale

- Horse Tack

Other uses for our rope

- Makes a simple, inexpensive toy for kids for hours of imaginative play.

- Cub Scouts and Boy Scouts use it to practice knot tying.

- Many dog leashes are made of this material as well as DIY dog toys

- This Polypropylene rope can be used to make an emergency rope ladder to be thrown out a window in case of a house fire

With a huge array of solid colors and color combinations, beautiful home décor items can also be made of this material.

- Rope-wrapped candle holders, vases, and decorative boxes

- Coasters, placemats, and rugs

- Picture frame hangers

- Rope towel holders for a nautical-themed bathroom

- Macrame plant hangers

- Fun, decorative rope letters to accent pillows or wall hangings.

Other Product Specifications of this versatile rope

Size Diameter Weight/1000’(lbs.)- Amish made in Conneautville, Pennsylvania

How Does Solid Braided Multifilament Polypropylene Rope Compare to Nylon or Polyester Rope?

They are all synthetic: Man-made fiber ropes are stronger and more durable than natural fiber ropes. They are generally not affected by rot, mildew, moths, and most chemicals and may be stored wet or dry. The service life of synthetic ropes exceeds that of natural fiber ropes and has proven to be more efficient and cost-effective.

Nylon- The strongest rope. Nylon's elasticity can absorb shock loads that would break ropes of other fibers. Resistant to abrasion, rot, petroleum products, marine growth and most chemicals. Nylon rope will last many times longer than natural fiber ropes. When wet, nylon rope has approximately 15% less strength and this should be considered when selecting nylon rope. If nylon rope is left out in the sunlight for prolonged periods, it will lose strength. Nylon will sink in water.

Polyester - has less stretch and elasticity than nylon plus greater resistance to ultraviolet degradation from sunlight. But if left out in the sunlight for prolonged periods, it too will lose strength. Other characteristics of the two fibers are practically the same.

Polypropylene - Extensively used for many applications, polypropylene is a strong, lightweight, floating rope. Resistant to rot, mildew, petroleum products, and most chemicals, polypropylene is an excellent all-purpose utility rope. This rope has good resistance to indirect sunlight.

The Process They Use to Manufacture Solid Braided Multifilament Polypropylene Rope

Manufacturing this type of Polypropylene Rope is an intensive process.

Leave a comment